The company was founded in 1991

Factory area of 20,000 square meters

Registered capital of 10 million yuan

More than 30 technical personnel

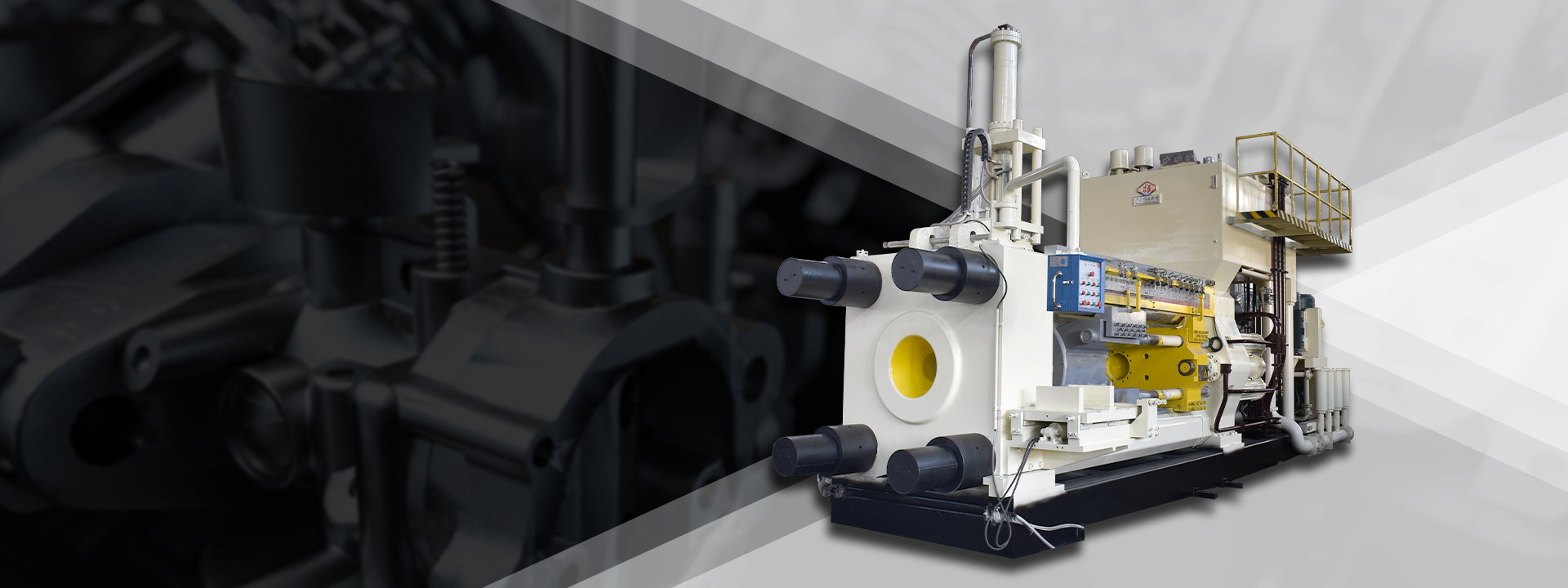

Product Display

The company's products are widely distributed throughout the country and Southeast Asia, Europe, and South America, and are well received by users.

Professional • High-quality • Efficient

Product Category

Email:xinke@xinkeyeya.com

Address:

No. 3, Kaixuan Road, Songgang Songxia Industrial Park, Shishan Town, Nanhai District, Foshan City, Guangdong Province

Xin Xinke Extrusion Machine Co., Ltd.

Taking product quality as the life of the enterprise, honesty and trustworthiness as the foundation, and user needs as the pursuit goal

Xinxinke Extrusion Press Co., Ltd. was founded in 1991 and is headquartered in Shishan Town, Foshan City, Guangdong Province. As one of China's leading manufacturers of copper and aluminum profile extrusion presses, the company specializes in the design, production, and development of extrusion machinery. Over three decades, Xinxinke has earned widespread recognition through relentless innovation, integration of advanced international technologies, and market-driven R&D. With nearly 200 employees, including 30 engineering professionals, we deliver presses spanning 660 UST to 11,000 UST tonnage capacities, renowned for their robust performance, operational efficiency, and aesthetic industrial design.

Rich technical experience

Advanced selection, design and manufacturing

Multiple patent certifications

Perfect service system

Blogs

The company's products are widely distributed throughout the country and Southeast Asia, Europe, and South America, and are well received by users.

Professional • High-quality • Efficient

Extrusion equipment is becoming increasingly popular

The working mechanism of an aluminum extrusion press

Precautions for operating an industrial aluminum extrusion press

Strengthen the maintenance of continuous extruder drive components

How does an extruder ensure that the interface is flat and the extruded material is cleanly cut?

Xin Xinke Advantages

The company's products are widely distributed throughout the country and Southeast Asia, Europe, and South America, and are well received by users.

Rich technical experience

The product is easy to operate and can meet the requirements of new and old customers, and is at the forefront of the domestic industry.

Quality Assurance

The company always adheres to its professional nature, introduces advanced foreign technologies, and the products have beautiful appearance, reliable performance, and stable quality.

Service Support

Our company has established itself with integrity, and with the business philosophy of Scientific Management, Service-Oriented, we have established a good corporate image in the industry.

Marketing Network

The company's products are widely distributed throughout the country and Southeast Asia, Europe, and South America, and are deeply loved and praised by a large number of users.

Xin Xinke Advantages

The company's products are widely distributed throughout the country and Southeast Asia, Europe, and South America, and are well received by users.

Rich technical experience

The product is easy to operate and can meet the requirements of new and old customers, and is at the forefront of the domestic industry.

Quality Assurance

The company always adheres to its professional nature, introduces advanced foreign technologies, and the products have beautiful appearance, reliable performance, and stable quality.

Service Support

Our company has established itself with integrity, and with the business philosophy of Scientific Management, Service-Oriented, we have established a good corporate image in the industry.

Marketing Network

The company's products are widely distributed throughout the country and Southeast Asia, Europe, and South America, and are deeply loved and praised by a large number of users.

Foshan Nanhai xinxinke extruder Co., Ltd

For many years, our company has established itself with integrity, and with the business philosophy of Scientific Management, Service-Oriented, we have established a good corporate image in the industry and become a leading domestic enterprise with obvious comprehensive advantages and core competitiveness.

Email:xinke@xinkeyeya.com

Address: No. 3, Kaixuan Road, Songgang Songxia Industrial Park, Shishan Town, Nanhai District, Foshan City, Guangdong Province

Contact Us